Laxmi Enterprises is one of the leading company in India that Optical Sorting Machines manufactures, supplies, dealers in India Optical Sorting Machines. They offer a huge variety of several variants of products to suit different needs of the market.

The optical sorting machine manufacturers, suppliers, dealers in India Company have made optical sorting machines that are easy to use and provide quick results. This helps them in winning the trust of their customers. They offer a wide range of products that can be customized according to the needs of the customer.

We optical sorting machine manufacturers, suppliers, dealers in India offer a wide range of products to suit different needs, including standard quality products as well as customized ones based on customer requirements.

Our optical sorting machine dealers in India Company give products which are known for their high quality and standard performance. They have also been able to establish themselves as one of the leading companies in their field.

Optical Sorting Machines are used to sort and classify products in a warehouse. They are used to speed up the process of picking, packing, and shipping.

These Sorting Machines are devices that sort items by size, shape, or colour. They are used in a variety of industries such as manufacturing, health care, and retail. These machines can be automated to make them more efficient and effective in their work.

The most common type of Optical Sorting Machine is the conveyor belt based machine. The sorting process is done on the belt. This machine has a series of light beams that are projected onto the material being sorted by using mirrors or lenses at each end of the belt.

Optical sorting machines are the future of warehouse management. They allow companies to automate processes and reduce labour costs by up to 70%. The use cases for optical sorting machines range from picking, packing, and shipping products in a warehouse to finding where inventory is located in the store.

They are used to sort different items by their sizes. The size of the items is determined by the wavelengths of light they reflect. This process is used in production lines where it helps to find and separate items quickly and easily.

The optical sorting machines require the minimal human intervention and are able to sort through large amounts of products quickly and efficiently.

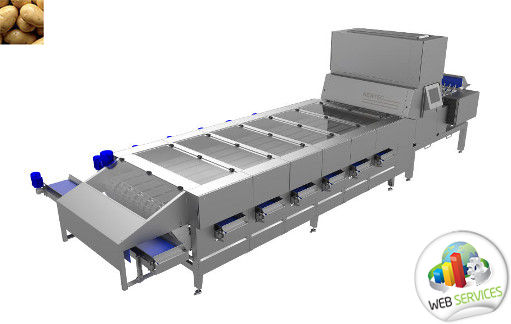

Newtec manufactures optical sorting machines for the type of potato that will work in your market and live up to your quality standards and pre-set classifications.

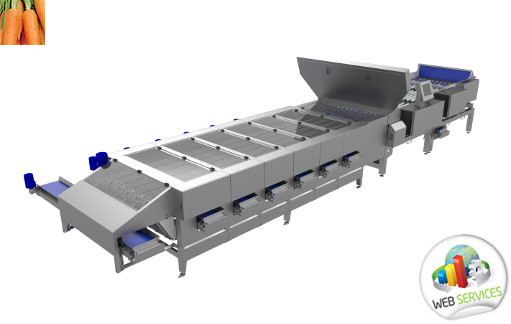

For more than twenty years, Newtec has developed and produced optical sorting machines for potatoes and carrots. Our Celox optical sorting machines are unique and world-leading machines in terms of technology and performance.

Our Celox contains patented technology and is the only machine on the market which can simultaneously grade products in both size, shape and quality - and then deliver the products in up to 14 different categories.

Products can thereby be split in the most suitable way to match orders and optimise earnings. Sorting of special product selections for trays, campaigns or customers are also possible.

We look forward to optimising the value of each of your potatoes and/or carrots by sorting them in the most profitable way.

We work in close cooperation with national and international researchers, scientists, universities and PhD students to identify new developments and insights that have the potential to transform the whole industry tomorrow.

Newtec is an active partner in the Open Science network.

Our software is adapted to the crop type that the machine is made for. The Celox machines use intelligent software which can be configured to detect specific defects on different surfaces. This means, for instance, that our Celox-P-UHD can sort almost any potato variety, taking into consideration that products tend to change during the season.

Consequently, the Celox machines bring high value to our customers not only by reducing labor cost, but because they optimise the value of every single potato or carrot by sorting them in the most profitable way, - all while handling the crop very gently.